Complete Fluid Containment for Hydrofluoric Alkylation Process Units

Operators of the Hydrofluoric (HF) acid alkylation process will know that the pumping of HF acid is an application that presents a set of truly unique challenges.

HMD Kontro have taken a unique and innovative approach, working in collaboration with UOP, to develop proven sealless pumps exclusively for use in HF alkylation units. We are now offering new HF alkylation process pumps with alternative C22 / C276 materials and a new method of NDE (Non-Destructive Examination) for the pump casing.

Due to the hazardous nature of HF acid in the alkylation process, it must be treated with the utmost care and, therefore, the HF alkylation units demand a fluid handling solution of the very highest standard, making magnetic drive pumps eminently suitable. By comparison, pumps featuring failure-prone mechanical seals can leak harmful process fluids, negatively impacting employee health, the environment and productivity.

HF Acid is also very challenging with respect to material selection, particularly with regard to cast components such as the pump casing and impeller. HF acid by its nature seeks out and attacks imperfections in cast components that will ultimately lead to reduced life and worst still, product leakage.

HMD Kontro sealless pumps provide a perfect solution offering the highest level of safety and reliability with absolutely no leakages, for complete fluid containment.

Download the Complete Fluid Containment for HF Alkylation Applications flyer:

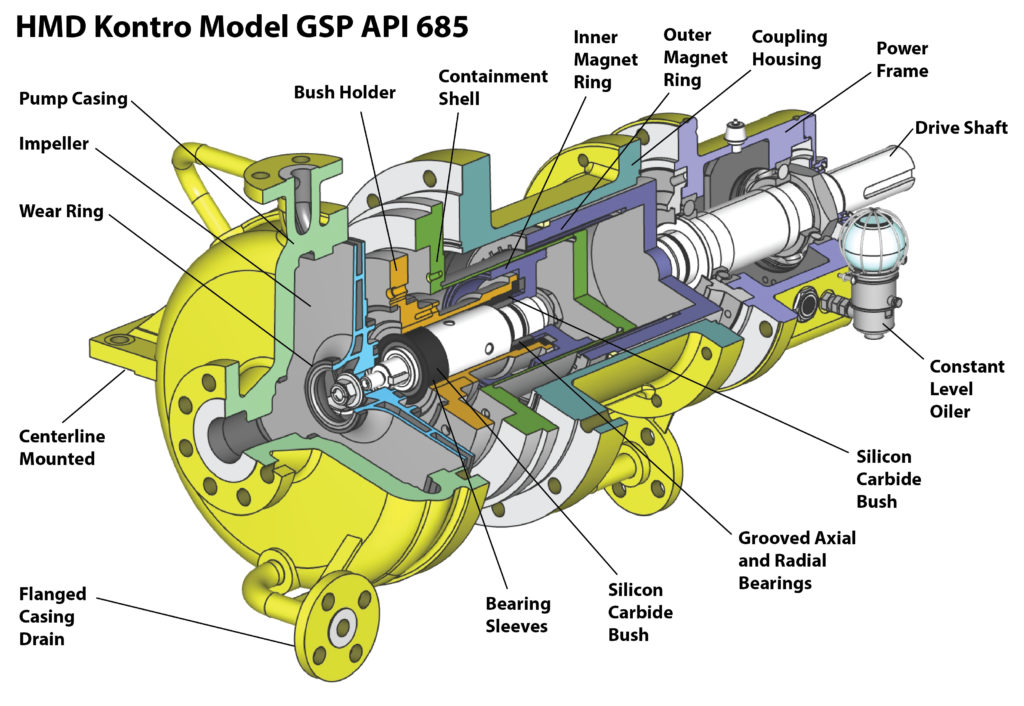

HMD Kontro Magnetic Drive Sealless Centrifugal Pumps for Hydrofluoric Acid Service

HMD has developed a pump design, specifically for the HF alkylation process, that contains key features and includes an identified core scope of equipment. This package must be supplied, as a minimum, on all pumps destined for an HF alkylation unit and contains the following benefits:

- Liquid contact materials of the highest grade

- NDE Requirements for HF Acid

- Secondary Containment – Rated to 40 Bar

- Leakage Detection Instrumentation

- Dry Run Pump Protection

Liquid Contact Materials of Construction for the HK Alkylation Process – Alloy C22/C276

HMD Kontro has standardised on Alloy C22/C276 materials of construction for HF Acid based on previous experience, validating their quality with our new methods of NDE. Using these materials in this tough application we have built an impressive portfolio of units providing users with years of uninterrupted operation.

If you would like further information, please leave your details below and a specialist HF Alkylation member of our team will be in touch!